|

| HISTORY OF SCANNER |

A scanner can refer to different things depending on the context. In the context of technology, a scanner is a device used to convert physical documents or images into digital format. It works by capturing the image or text from a physical source and creating a digital representation of it, which can then be stored, manipulated, or transmitted electronically. Scanners are commonly used in offices, homes, and various industries for tasks such as document archiving, image editing, and data entry.

There

are different types of scanners available, including flatbed scanners, sheet-fed

scanners, handheld scanners, and drum scanners. Flatbed scanners are the most common

type, resembling photocopiers with a glass surface where you place the document

or photo for scanning. Sheet-fed scanners are designed for scanning multiple documents

at once, and handheld scanners are portable and can be moved over a page by hand.

Drum scanners, which are less common nowadays, use rotating drums to capture high-resolution

images.

As for

"history," it can refer to various aspects:

- General

History: History is the study of past events, particularly in human societies.

It encompasses a wide range of subjects, such as political, social, economic,

cultural, and military events, that have shaped the world we live in today.

- Technological

History: This refers to the historical development and evolution of technology

over time. It involves studying inventions, innovations, and advancements

in various fields like computing, transportation, medicine, communication,

and more.

- Browser

History: In the context of the internet and web browsers, "history"

refers to the record of web pages and websites that a user has visited during

a specific period. Web browsers often keep a history list, allowing users to

revisit previously accessed websites easily.

- Search

History: Search history is a record of the searches made by a user on search

engines or websites. It helps improve user experience by providing personalized

search results and recommendations based on past searches.

Without

a specific context, it's challenging to provide a more detailed explanation of "scanner

and history." If you have a specific topic or area of interest related to these

terms, feel free to ask for more information.

A flatbed scanner. Documents or images are placed face-down beneath the cover (shown closed here).

An image scanner-often abbreviated

to just scanner-is a device that optically scans images, printed text, handwriting, or an object and converts it to a digital image. Commonly used in offices are variations

of the desktop flatbed scanner where the document is placed on a glass window

for scanning. Hand-held scanners, where the device is moved by hand, have

evolved from text scanning "wands" to 3D scanners used for industrial

design, reverse engineering, test and measurement, orthotics, gaming, and other applications.

Mechanically driven scanners that move the document are typically used for large-format

documents, where a flatbed design would be impractical.

Modern scanners typically use a charge-coupled

device (CCD) or a contact image sensor (CIS) as the image sensor, whereas drum

scanners, developed earlier and still used for the highest possible image quality,

use a photomultiplier tube (PMT) as the image sensor. A rotary scanner, used

for high-speed document scanning, is a type of drum scanner that uses a CCD array

instead of a photomultiplier. Non-contact planetary scanners essentially photograph

delicate books and documents. All these scanners produce two-dimensional images

of subjects that are usually flat, but sometimes solid; 3D scanners produce information

on the three-dimensional structure of solid objects.

Digital cameras can be used for the

same purposes as dedicated scanners. When compared to a true scanner, a camera image

is subject to a degree of distortion, reflections, shadows, low contrast, and blur

due to camera shake (reduced in cameras with image stabilization). Resolution is

sufficient for less demanding applications. Digital cameras offer the advantages of

speed, portability, and non-contact digitizing of thick documents without damaging

the book spine. In 2010 scanning technologies were combining 3D scanners with digital

cameras to create full-color, photo-realistic 3D models of objects.

Scans are usually downloaded by a computer

the unit is attached to. Some scanners are able to store scans on standalone flash

media (e.g. memory cards and USB sticks).

In the biomedical research area, detection

devices for DNA microarrays are called scanners as well. These scanners are high-resolution

systems (up to 1 µm/ pixel), similar to microscopes. The detection is done via CCD

or photomultiplier tubes.

History of scanners

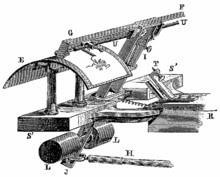

Pantelegraph

Caselli's pantelegraph mechanism

Belinograph BEP2V wire photo machine by Edouard Bélin, 1930

Modern scanners are considered the

successors of early telephotography and fax input devices.

The pantelegraph (Italian: pantelegrafo;

French: pantélégraphe) was an early form of facsimile machine transmitting

over normal telegraph lines developed by Giovanni Caselli, used commercially in

the 1860s, that was the first such device to enter practical service. It used electromagnets

to drive and synchronize the movement of pendulums at the source and the distant location,

to scan and reproduce images. It could transmit handwriting, signatures, or drawings

within an area of up to 150 × 100 mm.

Édouard Belin's Belinograph of 1913,

scanned using a photocell and transmitted over ordinary phone lines, formed the

basis for the AT&T Wirephoto service. In Europe, services similar to a wire photo were called a Belino. It was used by news agencies from the 1920s to the

mid-1990s and consisted of a rotating drum with a single photodetector at a standard

speed of 60 or 120 rpm (later models up to 240 rpm). They sent a linear analog AM

signal through standard telephone voice lines to receptors, which synchronously

print the proportional intensity on special paper. Color photos were sent as three

separate RGB-filtered images consecutively, but only for special events due to

transmission costs.

Types

Drum

The first image scanner developed for use with a computer was a drum scanner. It was built in 1957 at the US National Bureau of Standards by a team led by Russell A. Kirsch. The first image ever scanned on this machine was a 5 cm square photograph of Kirsch's then-three-month-old son, Walden. The black-and-white image had a resolution of 176 pixels on one side.

Drum scanners capture image information with photomultiplier

tubes (PMT), rather than the charge-coupled device (CCD) arrays found in flatbed

scanners and inexpensive film scanners. "Reflective and transmissive originals

are mounted on an acrylic cylinder, the scanner drum, which rotates at high speed

while it passes the object being scanned in front of precision optics that deliver

image information to the PMTs. Modern color drum scanners use three matched PMTs,

which read red, blue, and green light, respectively. Light from the original artwork

is split into separate red, blue, and green beams in the optical bench of the scanner

with dichroic filters." Photomultipliers offer superior dynamic range and for

this reason, drum scanners can extract more detail from very dark shadow areas of transparency than flatbed scanners using CCD sensors. The smaller dynamic range

of the CCD sensors, versus photomultiplier tubes, can lead to loss of shadow detail,

especially when scanning very dense transparency film. While mechanics vary by manufacturer,

most drum scanners pass light from halogen lamps through a focusing system to illuminate

both reflective and transmissive originals.

The drum scanner gets its name from

the clear acrylic cylinder, the drum, on which the original artwork is mounted for

scanning. Depending on size, it is possible to mount originals up to 20 by 28 inches

(510 mm × 710 mm), but the maximum size varies by manufacturer. "One of the unique

features of drum scanners is the ability to control sample area and aperture size

independently. The sample size is the area that the scanner encoder reads to create

an individual pixel. The aperture is the actual opening that allows light into the

optical bench of the scanner. The ability to control aperture and sample size separately

are particularly useful for smoothing film grain when scanning black-and-white and

color negative originals."

While drum scanners are capable of

scanning both reflective and transmissive artwork, a good-quality flatbed scanner

can produce good scans from reflective artwork. As a result, drum scanners are rarely

used to scan prints now that high-quality, inexpensive flatbed scanners are readily

available. The film, however, is where drum scanners continue to be the tool of choice

for high-end applications. Because film can be wet-mounted to the scanner drum,

which enhances sharpness and masks dust and scratches, and because of the exceptional

sensitivity of the PMTs, drum scanners are capable of capturing very subtle details

in film originals.

The situation as of 2014 was that only

a few companies continued to manufacture and service drum scanners. While prices

of both new and used units dropped from the start of the 21st century, they were

still much more costly than CCD flatbed and film scanners. The image quality produced

by flatbed scanners had improved to the degree that the best ones were suitable

for many graphic arts operations, and they replaced drum scanners in many cases

as they were less expensive and faster. However, drum scanners with their superior

resolution (up to 24,000 PPI), color gradation, and value structure continued to

be used for scanning images to be enlarged, and for museum-quality archiving of

photographs and print production of high-quality books and magazine advertisements.

As second-hand drum scanners became more plentiful and less costly, many fine-art

photographers acquired them.

Flatbed

This type of scanner is sometimes called

a reflective scanner because it works by shining white light onto the object to

be scanned and reading the intensity and color of light that is reflected from it,

usually a line at a time. They are designed for scanning prints or other flat, opaque

materials but some have available transparency adapters, which for a number of reasons,

in most cases, are not very well suited to scanning film.

CCD scanner

"A flatbed scanner is usually composed of a glass pane (or platen), under which there is a bright light (often xenon, LED, or cold cathode fluorescent) which illuminates the pane and a moving optical array in CCD scanning. CCD-type scanners typically contain three rows (arrays) of sensors with red, green, and blue filters."

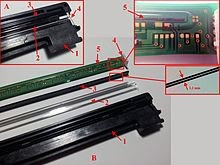

CIS scanner

Scanner unit with CIS. A: assembled, B: disassembled; 1: housing, 2: light conductor, 3: lenses, 4: chip with two RGB-LEDs, 5: CIS

Contact image sensor (CIS) scanning

consists of a moving set of red, green, and blue LEDs strobed for illumination and

a connected monochromatic photodiode array under a rod lens array for light collection.

"Images to be scanned are placed face down on the glass, an opaque cover is

lowered over it to exclude ambient light, and the sensor array and light source

move across the pane, reading the entire area. An image is therefore visible to

the detector only because of the light it reflects. Transparent images do not work

in this way and require special accessories that illuminate them from the upper

side. Many scanners offer this as an option."

Film

DSLR camera and slide scanner

This type of scanner is sometimes called

a slide or transparency scanner and it works by passing a narrowly focused beam

of light through the film and reading the intensity and color of the light that

emerges. "Usually, uncut film strips of up to six frames, or four mounted slides,

are inserted in a carrier, which is moved by a stepper motor across a lens and CCD

sensor inside the scanner. Some models are mainly used for same-size scans. Film

scanners vary a great deal in price and quality." The lowest-cost dedicated

film scanners can be had for less than $50 and they might be sufficient for modest

needs. From there they inch up in staggered levels of quality and advanced features

upward of five figures. "The specifics vary by brand and model and the end

results are greatly determined by the level of sophistication of the scanner's optical

system and, equally important, the sophistication of the scanning software."

Roller scanner

Scanners are available that pull a

flat sheet over the scanning element between rotating rollers. They can only handle

single sheets up to a specified width (typically about 210 mm, the width of many

printed letters and documents), but can be very compact, just requiring a pair of

narrow rollers between which the document is passed. Some are portable, powered

by batteries and with their own storage, eventually transferring stored scans to

a computer over a USB or other interface.

3D scanner

3D scanners collect data on the three-dimensional

shape and appearance of an object.

Planetary scanner

Planetary scanners scan delicate

objects without physical contact.

Hand

Hand scanners are moved over the subject

to be imaged by hand. There are two different types: document and 3D scanners.

Hand document scanner

A hand scanner with its interface module.

Hand-held document scanners are manual

devices that are dragged across the surface of the image to be scanned by hand.

Scanning documents in this manner requires a steady hand, as an uneven scanning

rate produces distorted images; an indicator light on the scanner indicates if the motion

is too fast. They typically have a "start" button, which is held by the

user for the duration of the scan; some switches to set the optical resolution;

and a roller, which generates a clock pulse for synchronization with the computer.

Older hand scanners were monochrome, and produced light from an array of green LEDs

to illuminate the image";[8] later ones scan in monochrome or color, as desired. A hand

scanner may have a small window through which the document being scanned could be

viewed. In the early 1990s, many hand scanners had a proprietary interface module

specific to a particular type of computer, such as an Atari ST or Commodore Amiga.

Since the introduction of the USB standard, it is the interface most commonly used.

As hand scanners are much narrower than most normal document or book sizes, software

(or the end-user) needed to combine several narrow "strips" of scanned

documents to produce the finished article.

Inexpensive portable battery-powered

"glide-over" hand scanners, typically capable of scanning an area as wide

as a normal letter and much longer remain available as of 2014.

Hand 3D scanner

Handheld 3D scanners are used in industrial

design, reverse engineering, inspection and analysis, digital manufacturing, and

medical applications. "To compensate for the uneven motion of the human hand,

most 3D scanning systems rely on the placement of reference markers, typically adhesive

reflective tabs that the scanner uses to align elements and mark positions in space."

Portable

Image scanners are usually used in

conjunction with a computer that controls the scanner and stores scans. Small portable

scanners, either roller-fed or "glide-over" hand-operated, operated by

batteries and with storage capability, are available for use away from a computer;

stored scans can be transferred later. Many can scan both small documents such as

business cards and till receipts, and letter-sized documents.

Keyboard document scanner

Example of the Imaging Keyboard-Scanner

A document scanner embedded inside

a computer keyboard makes it available when needed yet takes no extra space since

it is built inside the computer keyboard.

Smartphone scanner app

The higher-resolution cameras fitted

to some smartphones can produce reasonable quality document scans by taking a photograph

with the phone's camera and post-processing it with a scanning app, a range of which

are available for most phone operating systems, to whiten the background of a page,

correct perspective distortion so that the shape of a rectangular document is corrected,

convert to black-and-white, etc. Many such apps can scan multiple-page documents

with successive camera exposures and output them either as a single file or multiple-page files. Some smartphone scanning apps can save documents directly to online

storage locations, such as Dropbox and Evernote, and send via email or fax documents

via email-to-fax gateways.

Smartphone scanner apps can be broadly

divided into three categories:

1. Document scanning apps primarily designed to handle documents and output PDF,

and sometimes JPEG, files

2. Photo scanning apps that output JPEG files, and have editing functions useful

for photo rather than document editing;

3. Barcode-like QR code scanning apps that then search the internet for information

associated with the code.

Scan quality

Color scanners typically read RGB (red-green-blue

color) data from the array. This data is then processed with some proprietary algorithm

to correct for different exposure conditions and sent to the computer via the device's

input/output interface (usually USB, previous to which was SCSI or bidirectional

parallel port in older units).

Color depth varies depending on the scanning array

characteristics, but is usually at least 24 bits. High-quality models have 36-48

bits of color depth.

Another qualifying parameter for a

scanner is its resolution, measured in pixels per inch (ppi), sometimes more

accurately referred to as Samples per inch (spi). Instead of using the scanner's

true optical resolution, the only meaningful parameter, manufacturers like

to refer to the interpolated resolution, which is much higher thanks to software

interpolation. As of 2009, a high-end flatbed scanner can scan up to 5400 ppi and

drum scanners have an optical resolution of between 3,000 and 24,000 ppi.

"Effective resolution" is

the true resolution of a scanner, and is determined by using a resolution test chart.

The effective resolution of almost all consumer flatbed scanners is considerably lower

than the manufacturers' given optical resolution. An example is the Epson V750 Pro with

an optical resolution given by the manufacturer as being 4800dpi and 6400dpi (dual lens),

but tested "According to this we get a resolution of only about 2300 dpi -

that's just 40% of the claimed resolution!" Dynamic range is claimed to be

4.0 Dmax, but "Regarding the density range of the Epson Perfection V750 Pro,

which is indicated as 4.0, one must say that here it doesn't reach the high-quality

[of] film scanners either."

Manufacturers often claim interpolated

resolutions as high as 19,200 ppi; but such numbers carry little meaningful value because the number of possible interpolated pixels is unlimited and doing so does

not increase the level of captured detail.

The size of the file created increases

with the square of the resolution; doubling the resolution quadruples the file size.

A resolution must be chosen that is within the capabilities of the equipment, preserves

sufficient detail, and does not produce a file of excessive size. The file size

can be reduced for a given resolution by using "lossy" compression methods

such as JPEG, at some cost in quality. If the best possible quality is required

lossless compression should be used; reduced-quality files of smaller size can be

produced from such an image when required (e.g., an image designed to be printed on

a full page, and a much smaller file to be displayed as part of a fast-loading web

page).

Purity can be diminished by scanner

noise, optical flare, poor analog-to-digital conversion, scratches, dust, Newton's

rings, out-of-focus sensors, improper scanner operation, and poor software. Drum

scanners are said to produce the purest digital representations of the film, followed

by high-end film scanners that use the larger Kodak Tri-Linear sensors.

The third important parameter for a

scanner is its density range (Dynamic Range) or Drange (see Densitometry).

A high-density range means that the scanner is able to record shadow details and

brightness details in one scan. The density of the film is measured on a base 10 log scale

and varies between 0.0 (transparent) and 5.0, about 16 stops. The density range is the

space taken up in the 0 to 5 scale, and Dmin and Dmax denote where the least dense

and most dense measurements on a negative or positive film. The density range of

negative film is up to 3.6d, while the slide film dynamic range is 2.4d. Color negative

density range after processing is 2.0d thanks to the compression of the 12 stops into

a small density range. Dmax will be the densest on slide film for shadows, and densest

on negative film for highlights. Some slide films can have a Dmax close to 4.0d

with proper exposure, and so can black-and-white negative film.

Consumer-level flatbed photo scanners

have a dynamic range in the 2.0-3.0 range, which can be inadequate for scanning

all types of photographic film, as Dmax can be and often is between 3.0d and 4.0d

with traditional black-and-white film. The color film compresses its 12 stops of a possible

16 stops (film latitude) into just 2.0d of space via the process of dye coupling

and removal of all silver from the emulsion. Kodak Vision 3 has 18 stops. So, color-negative film scans the easiest of all film types on the widest range of scanners.

Because traditional black-and-white film retains the image-creating silver after

processing, the density range can be almost twice that of color film. This makes scanning

traditional black-and-white film more difficult and requires a scanner with at least

a 3.6d dynamic range, but also a Dmax between 4.0d to 5.0d. High-end (photo lab)

flatbed scanners can reach a dynamic range of 3.7, and Dmax around 4.0d. Dedicated

film scanners have a dynamic range between 3.0d-4.0d. Office document scanners can

have a dynamic range of less than 2.0d. Drum scanners have a dynamic range of 3.6-4.5.

By combining full-color imagery with

3D models, modern hand-held scanners are able to completely reproduce objects electronically.

The addition of 3D color printers enables accurate miniaturization of these objects,

with applications across many industries and professions.

For scanner apps, the scan quality

is highly dependent on the quality of the phone camera and on the framing chosen

by the user of the app.

Computer connection

A photographic print was scanned into a computer at the photo desk of the Detroit News in the early 1990s.

Scans must virtually always be transferred

from the scanner to a computer or information storage system for further processing

or storage. There are two basic issues: (1) how the scanner is physically connected

to the computer and (2) how the application retrieves the information from the scanner.

The direct physical connection to a computer

The file size of a scan can be up to

about 100 megabytes for a 600 DPI 23 x 28 cm (9"x11") (slightly larger

than A4 paper) uncompressed 24-bit image. Scanned files must be transferred and

stored. Scanners can generate this volume of data in a matter of seconds, making

a fast connection desirable.

Scanners communicate to their host

computer using one of the following physical interfaces, listing roughly from slow

to fast:

- Parallel port - Connecting through a parallel port is the slowest common transfer method. Early scanners had parallel port connections that could not transfer data faster than 70 kilobytes/second. The primary advantage of the parallel port connection was economic and user skill level: it avoided adding an interface card to the computer.

- GPIB - General Purpose Interface Bus. Certain drum scanners like the Howtek D4000 featured both a SCSI and GPIB interface. The latter conforms to the IEEE-488 standard, introduced in the mid-1970s. The GPIB interface has only been used by a few scanner manufacturers, mostly serving the DOS/Windows environment. For Apple Macintosh systems, National Instruments provided a NuBus GPIB interface card.

- Small Computer System Interface (SCSI), rarely used since the early 21st century, is supported only by computers with a SCSI interface, either on a card or built-in. During the evolution of the SCSI standard, speeds increased. Widely available and easily set up USB and Firewire largely supplanted SCSI.

- Universal Serial Bus (USB) scanners can transfer data quickly. The early USB 1.1 standard could transfer data at 1.5 megabytes per second (slower than SCSI), but the later USB 2.0/3.0 standards can transfer at more than 20/60 megabytes per second in practice.

- FireWire, or IEEE-1394, is an interface of comparable speed to USB 2.0. Possible FireWire speeds are 25, 50, 100, 400, and 800 megabits per second, but devices may not support all speeds.

- Proprietary interfaces were used on some early scanners that used a proprietary interface card rather than a standard interface.

Indirect (network) connection to a

computer

During the early 1990s professional

flatbed scanners were available over a local computer network. This proved useful

to publishers, print shops, etc. This functionality largely fell out of use as the

cost of flatbed scanners was reduced enough to make sharing unnecessary.

From 2000 all-in-one multi-purpose

devices became available which were suitable for both small offices and consumers,

with printing, scanning, copying, and fax capability in a single apparatus that

can be made available to all members of a workgroup.

Battery-powered portable scanners store

scans on internal memory; they can later be transferred to a computer either by

direct connection, typically USB, or in some cases a memory card may be removed

from the scanner and plugged into the computer.

Applications Programming Interface

A paint application such as GIMP or

Adobe Photoshop must communicate with the scanner. There are many different scanners,

and many of those scanners use different protocols. In order to simplify applications

programming, some Applications programming interfaces ("API") were developed.

The API presents a uniform interface to the scanner. This means that the application

does not need to know the specific details of the scanner in order to access it

directly. For example, Adobe Photoshop supports the TWAIN standard; therefore, in

theory, Photoshop can acquire an image from any scanner that has a TWAIN driver.

In practice, there are often problems

with an application communicating with a scanner. Either the application or the

scanner manufacturer (or both) may have faults in their implementation of the API.

Typically, the API is implemented as

a dynamically linked library. Each scanner manufacturer provides software that translates

the API procedure calls into primitive commands that are issued to a hardware controller

(such as the SCSI, USB, or FireWire controller). The manufacturer's part of the

API is commonly called a device driver, but that designation is not strictly accurate:

the API does not run in kernel mode and does not directly access the device. Rather

the scanner API library translates application requests into hardware requests.

Common scanner software API interfaces:

SANE (Scanner Access Now Easy) is a free/open-source

API for accessing scanners. Originally developed for Unix and Linux operating systems,

it has been ported to OS/2, Mac OS X, and Microsoft Windows. Unlike TWAIN, SANE

does not handle the user interface. This allows batch scans and transparent network

access without any special support from the device driver.

TWAIN is used by most scanners. Originally

used for low-end and home-use equipment, it is now widely used for large-volume

scanning.

ISIS (Image and Scanner Interface Specification)

created by Pixel Translations, which still uses SCSI-II for performance reasons,

is used by large, departmental-scale, machines.

WIA (Windows Image Acquisition) is an

API provided by Microsoft for use on Microsoft Windows.

Bundled applications

Although no software beyond a scanning

utility is a feature of any scanner, many scanners come bundled with the software. Typically,

in addition to the scanning utility, some type of image-editing application (such

as Adobe Photoshop), and optical character recognition (OCR) software are supplied.

OCR software converts graphical images of text into standard text that can be edited

using common word-processing and text-editing software; accuracy is rarely perfect.

Output data

Some scanners, especially those designed

for scanning printed documents, only work in black-and-white but most modern scanners

work in color. For the latter, the scanned result is a non-compressed RGB image,

which can be transferred to a computer's memory. The color output of different scanners

is not the same due to the spectral response of their sensing elements, the nature

of their light source, and the correction applied by the scanning software. While

most image sensors have a linear response, the output values are usually gamma compressed.

Some scanners compress and clean up the image using embedded firmware. Once on the

computer, the image can be processed with a raster graphics program (such as Adobe

Photoshop or GIMP) and saved on a storage device (such as a hard disk).

Images are usually stored on a hard

disk. Pictures are normally stored in image formats such as uncompressed Bitmap,

"non-lossy" (lossless) compressed TIFF and PNG, and "lossy"

compressed JPEG. Documents are best stored in TIFF or PDF format; JPEG is particularly

unsuitable for text. Optical character recognition (OCR) software allows a scanned

image of text to be converted into editable text with reasonable accuracy, so long

as the text is cleanly printed and in a typeface and size that can be read by the

software. OCR capability may be integrated into the scanning software, or the scanned

image file can be processed with a separate OCR program.

Document processing

Document scanner

Document imaging requirements differ

from those of image scanning. These requirements include scanning speed, automated

paper feed, and the ability to automatically scan both the front and the back of

a document. On the other hand, image scanning typically requires the ability to

handle fragile and or three-dimensional objects as well as scan at a much higher

resolution.

Document scanners have document feeders,

usually larger than those sometimes found on copiers or all-purpose scanners. Scans

are made at high speed, from 20 up to 280] or 420 pages per minute, often in

grayscale, although many scanners support color. Many scanners can scan both sides

of double-sided originals (duplex operation). Sophisticated document scanners have

firmware or software that cleans up scans of text as they are produced, eliminating

accidental marks and sharpening type; this would be unacceptable for photographic

work, where marks cannot reliably be distinguished from desired fine detail. Files

created are compressed as they are made.

The resolution used is usually from

150 to 300 dpi, although the hardware may be capable of 600[17] or higher resolution; this produces

images of text good enough to read and for optical character recognition (OCR),

without the higher demands on storage space required by higher-resolution images.

Document scans are often processed

using OCR technology to create editable and searchable files. Most scanners use

ISIS or TWAIN device drivers to scan documents into TIFF format so that the scanned

pages can be fed into a document management system that will handle the archiving

and retrieval of the scanned pages. Lossy JPEG compression, which is very efficient

for pictures, is undesirable for text documents, as slanted straight edges take

on a jagged appearance, and solid black (or other color) text on a light background

compresses well with lossless compression formats.

While paper feeding and scanning can

be done automatically and quickly, preparation and indexing are necessary and require

much work by humans. Preparation involves manually inspecting the papers to be scanned

and making sure that they are in order, unfolded, without staples or anything else

that might jam the scanner. Additionally, some industries such as legal and medical

may require documents to have Bates Numbering or some other mark giving a document

identification number and date/time of the document scan.

Indexing involves associating relevant

keywords to files so that they can be retrieved by content. This process can sometimes

be automated to some extent, but it often requires manual labor performed by data-entry

clerks. One common practice is the use of barcode-recognition technology: during

preparation, barcode sheets with folder names or index information are inserted

into the document files, folders, and document groups. Using automatic batch scanning,

the documents are saved into appropriate folders, and an index is created for integration

into document-management systems.

A specialized form of document scanning

is book scanning. Technical difficulties arise from the books usually being bound

and sometimes fragile and irreplaceable, but some manufacturers have developed specialized

machinery to deal with this. Often special robotic mechanisms are used to automate

the page-turning and scanning process.

Document camera scanners

Another category of document scanner

is the document camera. Capturing images on document cameras differs from

that of flatbed and Automatic document feeder (ADF) scanners in that there are no

moving parts required to scan the object. Conventionally either the illumination/reflector

rod inside the scanner must be moved over the document (such as for a flatbed scanner),

or the document must be passed over the rod (such as for feeder scanners) in order

to produce a scan of a whole image. Document cameras capture the whole document

or object in one step, usually instantly. Typically, documents are placed on a flat

surface, usually the office desk, underneath the capture area of the document camera.

The process of whole-surface-at-once capturing has the benefit of increasing reaction

time for the workflow of scanning. After being captured, the images are usually

processed through software that may enhance the image and perform such tasks as

automatically rotating, cropping, and straightening them.

It is not required that the documents

or objects being scanned make contact with the document camera, therefore increasing the flexibility of the types of documents which are able to be scanned. Objects which

have previously been difficult to scan on conventional scanners are now able to

be done so with one device. This includes in particular documents that are of varying

sizes and shapes, stapled, in folders, or bent/crumpled which may get jammed in a

feed scanner. Other objects include books, magazines, receipts, letters, tickets, etc. No moving parts can also remove the need for maintenance, a consideration in

the Total cost of ownership, which includes the continuing operational costs of

scanners.

Increased reaction time whilst scanning

also has benefits in the realm of context scanning. ADF scanners, whilst very fast

and very good at batch scanning, also require pre-and post-processing of the documents.

Document cameras can be integrated directly into a Workflow or process, for example, a teller at a bank. The document is scanned directly in the context of the customer,

in which it is to be placed or used. Reaction time is an advantage in these situations.

Document cameras usually also require a small amount of space and are often portable.

Whilst scanning with document cameras

may have a quick reaction time, large amounts of batch scanning of even, unstapled

documents is more efficient with an ADF scanner. There are challenges that face

this kind of technology regarding external factors (such as lighting) which may

have an influence on the scan results. The way in which these issues are resolved strongly

depends on the sophistication of the product and how it deals with these issues.

Infrared cleaning

Infrared cleaning is a technique used to remove the

effects of dust and scratches on images scanned from film; many modern scanners

incorporate this feature. It works by scanning the film with infrared light; the

dyes in typical color film emulsions are transparent to infrared light, but dust

and scratches are not, and block infrared; scanner software can use the visible

and infrared information to detect scratches and process the image to greatly reduce

their visibility, considering their position, size, shape, and surroundings.

Scanner manufacturers usually have

their own names attached to this technique. For example, Epson, Minolta, Nikon, Konica

Minolta, Microtek, and others use Digital ICE, while Canon uses its own system FARE

(Film Automatic Retouching and Enhancement System). Plustek uses LaserSoft Imaging

iSRD. Some independent software developers design infrared cleaning tools.

Other uses

Flatbed scanners have been used as

digital backs for large-format cameras to create high-resolution digital images

of static subjects. A modified flatbed scanner has been used for documentation and

quantification of thin-layer chromatograms detected by fluorescence quenching on

silica gel layers containing an ultraviolet (UV) indicator. 'ChromImage' is allegedly

the first commercial flatbed scanner densitometer. It enables the acquisition of TLC

plate images and quantification of chromatograms by use of Galaxie-TLC software.

Other than being turned into densitometers, flatbed scanners were also turned into

colorimeters using different methods. Trichromatic Color Analyser is allegedly the

first distributable system using a flatbed scanner as a tristimulus colorimetric

device.

0 Comments